HERCULES 12 in., 80T Fine Finish Miter Saw Blade

- The HERCULES® 12 in., 80T Fine Finish Miter Saw Blade delivers exceptional performance with full-blade ELECTRA SHIELD® nonstick coating to prevent burning, sticking and gumming. The HERCULES® table saw blade is constructed with premium tungsten carbide cutting teeth, deeper gullets and anti-kickback design for long lasting performance.

- Premium tungsten carbide teeth stay sharper longer for ultimate performance and durability

- Deeper gullets remove material at a faster rate for super fast cuts

- Extra thin kerf for precise cuts

- Anti-kickback design for cleaner finish and less splintering

- Alternate top bevel tooth design for efficient material removal

- ELECTRA SHIELD® nonstick coating for fast, fine smooth cuts

$39.99

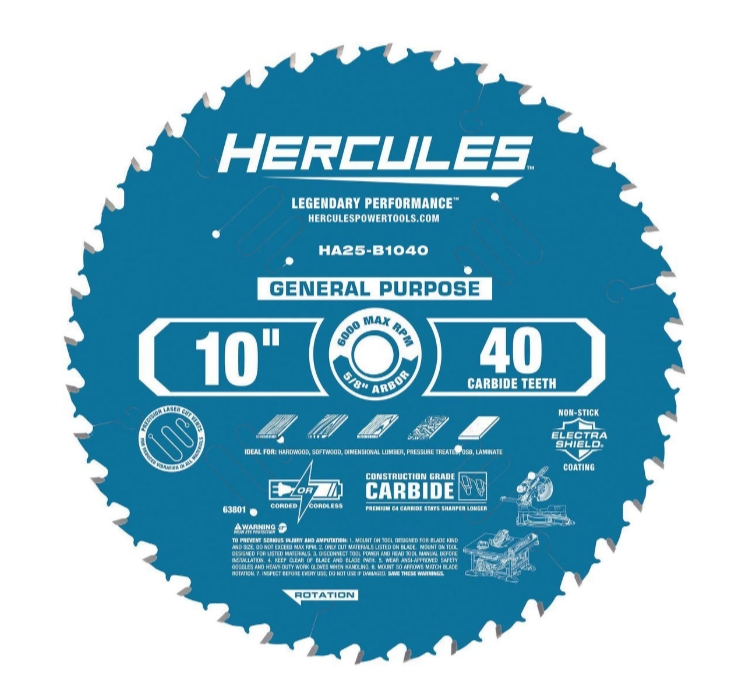

HERCULES 10 in., 40T General Purpose Miter and Table Saw Blade

- The HERCULES® 10 in., 40T General Purpose Miter and Table Saw Blade makes fast, clean cuts in hardwood, softwood, dimensional lumber, pressure treated wood, OSB, and laminate. Razor-sharp premium tungsten carbide cutting edges can be resharpened for exceptionally long blade life. The ELECTRA SHIELD® nonstick coating prevents gumming and burning. Laser-cut expansion vents and vibration channels keep the blade straight and true.

- Premium tungsten carbide teeth stay sharper longer for ultimate performance and durability

- Deeper gullets remove material at a faster rate for super fast cuts

- Extra thin kerf for precise cuts

- Anti-kickback design for cleaner finish and less splintering

- Alternate top beval tooth design for efficient material removal

- ELECTRA SHIELD® nonstick coating for fast, fine smooth cuts

$24.99

HERCULES 14 in., 66T Cermet Carbide Circular Saw Blade for Metal Cutting Saws with 1 in. Arbor

- This HERCULES™ 14 in., 66T Cermet Carbide Circular Saw Blade is specially engineered for cutting steel studs, angle iron, threaded rod, EMT conduit. Construction grade cermet carbide teeth deliver the best performance for cutting stainless steel and metal.

- Premium tungsten cermet teeth have high heat tolerance for ultimate performance and durability

- Blade transfers heat away from the material for cool-to-the-touch cuts

- Ultra sharp teeth cut faster and cleaner than abrasive wheels meaning no burrs, sparks, or dust

- Cermet teeth have high heat tolerance and and increased hardness for long life

- Triple chip grind tooth design for efficient material removal

$74.99

HERCULES 10 in., 84T Laminate/Plastics/Non-Ferrous Metal Cutting Miter And Table Saw Blade

- The HERCULES™ 10 in., 84T Laminate/Plastics/Non-Ferrous Metal Cutting Miter And Table Saw Blade combines premium carbide tips and maximum rigidity for superior blade life that runs truer longer. The beveled tooth design offers extreme durability in the hardest materials. Non-stick Electra-Shield® coating prevents sticking, gumming or burning. Ideal for copper pipe, aluminum tubing, PVC, brass rod, fiberglass, and laminate

- Premium tungsten carbide teeth stay sharper longer

- Deeper gullets to remove material rapidly for superior fast cuts

- Extra-thin kerf for more precise cuts

- Precision laser-cut vents for reduced vibration in all materials

- Anti-kickback design for reduced material kickback

- Triple chip grind tooth design for efficient material removal

- Designed for use with premium corded or cordless saws

$39.99

HERCULES 7-1/4 in., 48T Steel Cutting Circular Saw Blade

- The HERCULES™ 7-1/4 in., 48T Steel Cutting Circular Saw Blade cuts through steel studs, angle iron, threaded rod, and EMT conduit. Premium cermet carbide teeth provide the highest heat tolerance for longer blade life in both metal and stainless steel. Cool-to-the-touch cuts transfers heat away from the material with no abrasive dust.

- Premium tungsten cermet teeth stay sharper longer for ultimate performance and durability

- Deeper gullets to remove material rapidly for superior fast cuts

- Extra-thin kerf for precise, cool, ultra-narrow cuts

- Anti-kickback tooth design for reduced material kickback

- Triple-chip grind tooth design for extreme durability in the hardest materials

- Designed for use with corded or cordless saws

$29.99

As I stood in my workshop last weekend, staring at a pile of materials that needed cutting and a collection of saw blades that had definitely seen better days, I realized it was time for an upgrade. After hours of research and hands-on testing, I’ve put together this comprehensive guide to Hercules saw blades – a brand that’s been gaining serious traction in both DIY and professional circles.

If you’re like me, you want the perfect balance of performance and value without sacrificing quality. That’s exactly what led me to explore the Hercules line, and I’m excited to share everything I’ve learned along the way.

Understanding the Hercules Blade Lineup

When I first started looking into Hercules saw blades, I was surprised by the variety of options available. The brand has quietly built up an impressive range that covers virtually every cutting need you might encounter. Let me break down the main types I’ve discovered:

Circular Saw Blades

The cornerstone of the Hercules lineup has to be their circular saw blades. These workhorses come in various diameters, with 7-1/4″ being the most common size I’ve encountered. What I appreciate most is the range of tooth counts available – from 24-tooth framing blades that zip through dimensional lumber like butter, to 60-tooth finishing blades that leave edges smooth enough to make a cabinetmaker smile.

I recently used their 40-tooth combination blade to build a set of bookshelves, and the versatility impressed me. It handled crosscuts in hardwood with minimal tearout while still making quick work of ripping operations. The anti-kickback design gave me confidence when making longer cuts, and I noticed significantly less vibration compared to my old blade.

The Hercules circular saw blades feature carbide tips that are noticeably thicker than some competitor blades I’ve used in the past. This means they can withstand several sharpenings before needing replacement – a detail that matters when you’re calculating the true cost of ownership.

Miter Saw Blades

For precision crosscuts and angle work, Hercules offers specialized miter saw blades that have become my go-to for trim work. The distinction between these and their circular saw counterparts isn’t just marketing – I’ve found genuine differences in the tooth geometry that make a real difference in cut quality.

The 10″ 80-tooth miter blade I purchased three months ago has made crown molding installation dramatically easier. The laser-cut expansion slots keep the blade running true even after heating up, and the special tooth grind leaves minimal sanding work – crucial when you’re dealing with pre-finished materials.

What surprised me was how well these blades handle hardwoods. I recently worked with some notoriously difficult maple, and the Hercules blade powered through with minimal burning and almost no chipout. The anti-vibration design also means my cut lines are exactly where I mark them, not “sort of close” like with my previous setup.

Table Saw Blades

The table saw is the centerpiece of most workshops, and blade quality makes or breaks your results. Hercules offers specific table saw blades designed to handle the continuous cutting these tools often endure.

Their 10″ 50-tooth combination blade has become my everyday workhorse. The alternating top bevel (ATB) tooth pattern delivers clean cuts in both solid wood and sheet goods, while the reinforced shoulder design handles the stresses of all-day ripping operations.

I’ve found that their table saw blades feature slightly thinner kerfs than their circular saw counterparts – a design choice that reduces strain on the motor and allows for smoother feeding. The precision-ground teeth maintain their edge remarkably well, even when I’m working with resinous pine that would gum up lesser blades.

Specialty Blades

Beyond the standard offerings, Hercules has developed specialty blades that have saved me countless headaches:

- Diamond-tipped masonry blades that have handled everything from brick to concrete pavers

- Metal-cutting blades with specially designed teeth that made short work of aluminum trim and even mild steel

- Plywood and laminate blades with high tooth counts that leave zero splintering on veneer faces

- Thin-kerf blades that maximize battery life on my cordless saws

I was particularly impressed with their oscillating multi-tool blades, which outlasted my previous brand by at least 3:1 when cutting through nail-embedded wood during a renovation project.

Material Compatibility: What Can Hercules Blades Cut?

One of the biggest questions I had before investing in Hercules blades was material compatibility. After putting them through their paces across a wide range of projects, here’s what I’ve learned:

Wood and Wood Products

This is where Hercules truly shines. Their carbide-tipped blades handle everything from soft pine to rock-hard maple with consistent results. What I’ve come to appreciate most is how well they manage engineered materials like:

- MDF and particleboard (minimal fuzzing on the edges)

- Plywood (clean cuts with no splintering on veneer faces)

- Melamine and laminated products (no chipping along the cut line)

- Pressure-treated lumber (despite the high moisture content and preservatives)

I recently completed a project using reclaimed barn wood – material that often contains hidden nails and dirt that can destroy lesser blades. The Hercules blade barely showed any wear even after encountering a few surprise nails.

Metals

While specialized metal-cutting tools are always preferable for serious metalwork, I’ve found Hercules blades surprisingly capable when it comes to light metal cutting tasks:

- Aluminum trim and extrusions cut cleanly with their dedicated metal blades

- Thin steel (up to about 1/8″) is manageable with their ferrous metal blades

- Copper pipe and brass rod cut without grabbing or binding

The key difference I’ve noticed is the special tooth geometry on their metal-specific blades, which prevents the “catching” that can be dangerous with regular wood blades. The teeth are also optimized to dissipate heat more effectively, extending the life of both the blade and your saw.

Masonry and Tile

Hercules diamond blades have become indispensable for my occasional tile and masonry work. They’ve successfully handled:

- Ceramic tile (with minimal chipping on glazed surfaces)

- Porcelain tile (slower feed rate required but clean results)

- Concrete pavers and blocks

- Brick and stone

What impressed me most was using their 4.5″ diamond blade to cut a channel for electrical conduit in a concrete block wall. The blade maintained consistent cutting depth throughout the project without glazing over – something my previous brand failed to do.

Composites and Plastics

Modern building materials often present unique cutting challenges. I’ve successfully used Hercules blades on:

- Fiber cement siding (using their specialized blade with dust collection)

- Vinyl siding and PVC trim

- Composite decking materials

- Acrylic sheet and other plastics

The key I’ve found with these materials is using the correct blade and adjusting feed rate accordingly. For example, cutting PVC trim works best with a higher tooth count blade at moderate speeds to prevent melting.

Hercules vs. Competitors: The Honest Comparison

I’ve used blades from most major manufacturers over the years, and positioning Hercules in the marketplace is interesting. They occupy what I consider the “prosumer” sweet spot – professional quality without the premium price tag of top-tier brands.

Performance Comparison

When compared to budget brands (those typically selling for 30-50% less), Hercules blades offer noticeably superior performance:

- Significantly longer edge retention – I’ve found they maintain sharpness through about twice as many cuts

- Reduced vibration for smoother, more accurate cutting

- Better balance that translates to less wandering on long cuts

- Superior materials that resist heat buildup during extended use

Against premium brands (those selling for 30-50% more), the comparison gets interesting:

- Edge life is comparable for most common applications

- Cut quality is nearly identical in standard materials

- Vibration control is similar especially in their higher-end blades

- Slightly less durability when faced with extreme abuse (embedded nails, etc.)

I recently conducted an impromptu test when helping a friend with a kitchen renovation. We used his premium brand blade for half the cabinet cuts and my Hercules blade for the remainder. When examining the finished edges side by side, neither of us could consistently identify which blade made which cut – but the Hercules blade cost about 40% less.

Value Proposition

This is where Hercules truly stands out. After tracking costs across multiple projects, I’ve calculated that Hercules blades offer approximately 80-90% of premium brand performance at 60-70% of the cost. For professionals, this can significantly impact the bottom line over a year of projects.

For weekend warriors like myself, the math is even more compelling – the blades perform well enough for professional-looking results but at a price point that’s easier to justify for occasional use.

Where to Purchase and Price Expectations

One limitation of Hercules is more restricted availability compared to some mainstream brands. I’ve found them primarily at:

- Harbor Freight stores (their exclusive retail partner)

- Harbor Freight’s online store

- Occasionally through third-party sellers online (though be cautious about authenticity)

This limited distribution actually works in favor of consistent pricing, which I appreciate as a consumer. You’re not likely to find significant price variations between different retailers.

Price Points

Based on my purchases over the past year, here’s what you can expect to pay for Hercules saw blades:

- Standard 7-1/4″ circular saw blades: $15-30 depending on tooth count and purpose

- 10″ miter/table saw blades: $30-50 depending on specification

- Specialty blades (diamond, metal-cutting): $25-60 depending on size and purpose

- Oscillating multi-tool blades: $10-20 for individual blades, $30-45 for sets

What I’ve noticed is that Hercules frequently runs promotions and sales that can reduce these prices by 15-25%, making strategic purchasing worthwhile. I’ve taken to stocking up during these sale periods for blades I use regularly.

Woodworking with Hercules Blades: The Real-World Experience

As someone who’s completed everything from rough framing to fine furniture with these blades, I can speak to their woodworking capabilities in detail.

Fine Woodworking Applications

For precision cuts in hardwoods and fine materials, I’ve found their high tooth count blades (60T and above) perform admirably:

- Crosscuts in hardwood show minimal tearout, even in traditionally difficult species like oak

- Miter joints close tightly without gaps caused by blade deflection

- Veneer faces remain chip-free when using the appropriate blade

- Glue-ready edges require minimal jointing before assembly

The 80-tooth miter blade particularly impressed me when cutting complex compound angles for a six-sided display case. The edges came off the saw clean enough to glue without additional preparation.

Construction and Rough Carpentry

For framing and general construction, their lower tooth count blades (24T-40T) deliver the speed and durability needed:

- Dimensional lumber cuts quickly with minimal binding

- Engineered joists and beams cut cleanly without splintering

- The teeth resist dulling even when cutting treated lumber

- The anti-kickback design has saved me from potential issues more than once

I recently framed an entire garden shed using a single Hercules framing blade, and it remained sharp enough to use for the finish trim work afterward – impressive longevity that translates to real cost savings.

Metal Cutting Capabilities

While I don’t often cut metal, having the capability has been unexpectedly useful. Hercules metal-cutting blades have handled:

- Aluminum window trim and flashing

- Light gauge steel studs and track

- Conduit and thin-walled pipe

- Unistrut and angle iron for shop fixtures

The key difference I’ve noticed compared to budget metal blades is heat management. The Hercules blades dissipate heat more effectively, which not only extends blade life but also prevents work hardening on the cut edges of the metal.

Durability and Longevity: The Long-Term Value

Any discussion of saw blade value must consider longevity. After tracking several Hercules blades through their lifecycle, here’s what I’ve found:

Edge Retention

On average, I get about 20-30% more cuts from a Hercules blade before noticeable performance decline compared to similarly priced competitors. In practical terms, this meant my 40T combination blade maintained clean cuts through approximately 500 linear feet of mixed hardwoods before requiring sharpening.

Resilience to Abuse

We all occasionally hit something we shouldn’t with our blades. I’ve accidentally cut through hidden nails, staples, and even a forgotten clamp with Hercules blades. While no blade emerges unscathed from such encounters, I’ve been impressed by how often I could simply replace a damaged tooth or two rather than discard the entire blade.

Sharpening Potential

The carbide used in Hercules blades is thick enough to allow for multiple resharpenings – something not true of all blades in this price range. I’ve had three blades professionally resharpened, each regaining about 90% of their original performance. At approximately $15-20 per sharpening, this extends the economic value substantially.

Available Sizes and Compatibility

Hercules offers blades in all standard sizes, making compatibility rarely an issue:

- Circular saw blades: 5-3/8″, 6-1/2″, 7-1/4″, 8-1/4″

- Table/miter saw blades: 8″, 10″, 12″

- Specialty sizes: 4-1/2″ for small angle grinders, various oscillating tool fitments

I’ve successfully used their blades on tools from DeWalt, Milwaukee, Makita, Bosch, and Ryobi without any fitment issues. The arbor holes are precisely machined, resulting in minimal runout when properly mounted.

Consumer and Professional Reviews

I’m not alone in my positive assessment of Hercules blades. Across contractor forums and DIY communities, they’ve developed a solid reputation as a value leader. The consistent themes I’ve seen in reviews align with my experience:

- Professionals appreciate the economy when purchasing blades that may face job site abuse

- DIYers value the performance that exceeds typical “homeowner grade” options

- Both groups note the excellent balance of price and performance

A contractor friend summed it up well: “They’re not what I’d choose for a museum-quality furniture piece, but for 95% of what I build for clients, they’re exactly what I need at a price that keeps me competitive.”

Circular vs. Miter Saw Blades: Understanding the Differences

While there’s some overlap between blade types, I’ve learned that the distinctions between circular and miter saw blades in the Hercules line are meaningful:

Circular Saw Blades

These are designed with considerations for:

- Hand-held operation (more stable tooth geometry to reduce grabbing)

- Diverse cutting positions (reinforced teeth to handle varied stresses)

- Generally rougher work (thicker carbide for durability)

- More ripping operations (larger gullets between teeth groups)

Miter Saw Blades

These optimize for:

- Fixed position operation (finer tooth geometry possible)

- Primarily crosscutting (tooth angles optimized accordingly)

- Finish work (higher tooth counts and special grinds for clean cuts)

- Consistent angles (anti-vibration features to maintain precision)

While you can interchange these in a pinch, I’ve found respecting these design differences leads to better results and longer blade life.

Warranty Coverage and Support

Hercules backs their blades with a satisfaction guarantee that I’ve found to be straightforward and hassle-free. While not the longest warranty in the industry, it covers manufacturing defects and premature failure under normal use.

My one experience with warranty service was positive – a 60T blade that developed a wobble after just a few weeks was replaced without question at my local Harbor Freight. The process took less than five minutes with my original receipt.

For professionals considering these blades, it’s worth noting that the warranty support is store-based rather than through a dedicated professional service channel, which might be a consideration for those who need immediate replacement options.

Professional Viability: Can Pros Rely on Hercules?

As someone who straddles the line between serious hobbyist and occasional paid work, I’ve wondered if full-time professionals can rely on Hercules blades. Based on my experience and discussions with contractor friends, the answer is qualified but positive.

Where Hercules Excels for Pros

- General construction and remodeling where blade replacement is a regular cost of doing business

- Trim carpentry where the finish quality is excellent but the ultimate premium isn’t required

- Mixed material jobs where dedicated specialty blades would be overkill

- Educational settings where performance matters but budget constraints are real

Where Professionals Might Look Elsewhere

- Ultra-fine furniture making where the absolute pinnacle of cut quality justifies premium pricing

- Production shops where maximizing blade life between sharpenings is economically critical

- Specialized applications like architectural millwork where tight tolerances are non-negotiable

The consensus among my professional contacts is that Hercules blades make excellent “daily drivers” while keeping a few premium specialized blades on hand for those critical applications where cost is no object.

Tooth Configurations and Choosing the Right Blade

One of the most important aspects of selecting the right Hercules blade is understanding the available tooth configurations and their purposes:

Flat Top Grind (FTG)

Best for:

- Ripping solid wood with the grain

- Fast cutting where finish quality is secondary

- Removing material efficiently

I use their 24T FTG blade almost exclusively for ripping framing lumber and rough dimensioning hardwoods.

Alternate Top Bevel (ATB)

Best for:

- General purpose cutting

- Crosscutting with clean edges

- Plywood and sheet goods

Their 40T ATB has become my go-to combination blade that stays mounted on my circular saw for most projects.

Triple Chip Grind (TCG)

Best for:

- Non-ferrous metals

- Hard plastics

- Laminated materials with hard surfaces

I’ve found their TCG blades particularly effective when cutting aluminum composite panels and melamine-faced particleboard.

High Alternate Top Bevel (Hi-ATB)

Best for:

- Ultra-clean crosscuts

- Fine veneers and delicate materials

- Precision detail work

The 80T Hi-ATB blade produced the cleanest cuts I’ve achieved when working on a display case with figured maple veneer.

Understanding these configurations has allowed me to select the right tool for each job rather than compromising with a single all-purpose blade.

Masonry and Tile Applications

While not their primary focus, Hercules diamond blades have proven capable for my occasional masonry work:

- The continuous rim blades deliver clean cuts in ceramic tile

- Segmented blades make quick work of concrete and brick

- Turbo-style blades offer a good compromise for mixed masonry projects

What I’ve appreciated most is their durability – the 7″ diamond blade I purchased for a bathroom renovation two years ago continues to perform well for occasional projects, despite sitting unused for months between applications.

Blade Maintenance and Sharpening

Proper maintenance significantly extends blade life, and I’ve developed a routine that serves well for Hercules blades:

Cleaning Routine

I clean my blades after any significant use with a dedicated blade cleaner or simple pine-based cleaner to remove pitch and resin buildup. The Hercules blades seem particularly resistant to resin adhesion compared to some other brands I’ve used, but regular cleaning still makes a noticeable difference in performance.

Professional Sharpening

When performance begins to decline, I’ve had excellent results having Hercules blades professionally resharpened. At about $1-2 per tooth, this is substantially more economical than replacement, especially for higher tooth count blades.

The thick carbide tips allow for multiple resharpenings before replacement becomes necessary – I’ve had one favorite 60T blade resharpened three times over two years of regular use, making the effective cost per month remarkably low.

DIY Sharpening Limitations

While diamond files can touch up minor dulling, I’ve found attempting complete DIY resharpening of carbide-tipped blades rarely produces satisfactory results. The precision required to maintain proper tooth geometry and angles is difficult to achieve without specialized equipment.

Compatibility with Cordless Tools

As battery tools have taken over more of my workflow, I’ve paid particular attention to how Hercules blades perform with cordless saws. The results have been impressive:

- Their thin-kerf options significantly extend battery life on my 20V circular saw

- The precision balancing reduces vibration, further conserving energy

- The clean cutting action requires less force, again improving efficiency

I recently built an entire deck using exclusively cordless tools, and the Hercules blade’s efficiency was noticeable – I could complete about 30% more cuts per battery charge compared to the stock blade that came with the saw.

Lifetime Value Assessment

Looking at total cost of ownership has convinced me of the value proposition Hercules blades offer. Taking a typical 10″ 60T blade as an example:

- Initial purchase: Approximately $45

- Expected cuts before first resharpening: ~750-1000 linear feet of hardwood

- Resharpening cost: ~$20

- Additional life after resharpening: ~80% of original

- Potential for 2-3 resharpenings before replacement

This works out to an effective cost of about $0.03-0.04 per linear foot of hardwood cutting – a value that compares favorably to both budget and premium alternatives when factoring in the quality of cuts produced.

Safety Considerations

No blade discussion would be complete without addressing safety, which goes beyond the blade itself to proper usage practices:

Blade-Specific Safety Features

Hercules incorporates several safety features that I’ve come to appreciate:

- Anti-kickback tooth design that limits aggressive biting

- Expansion slots that reduce warping under heat

- Vibration-dampening that improves control and accuracy

Personal Safety Practices

When using any saw blade, including Hercules products, I strictly adhere to these practices:

- Always wearing appropriate eye protection and hearing protection

- Using blade guards and riving knives as designed

- Ensuring proper blade installation and tightening

- Inspecting blades for damage before each use

- Using push sticks and other aids to keep hands away from cutting edges

- Ensuring material is properly supported to prevent binding

I’ve found that the stability and predictable cutting action of quality blades like those from Hercules actually contributes significantly to safety by reducing unexpected binding and grabbing during operation.

Making Your Hercules Blade Selection

After working extensively with these blades, here’s my practical advice for selecting the right Hercules blade for your needs:

For the Occasional DIYer

- Start with a good 40T combination blade for your circular saw

- Add a 60T or 80T blade for your miter saw if you do trim work

- Consider a specialty blade only when you have a specific project that requires it

For the Serious Hobbyist

- Invest in three circular saw blades: 24T for rough work, 40T for general purpose, and 60T for fine cuts

- For table and miter saws, have both a 40T general purpose and 80T finish blade

- Add specialty blades for the materials you work with most often

For the Professional

- Maintain a full complement of task-specific blades to maximize efficiency

- Consider keeping backup blades for your most-used configurations

- Develop a relationship with a local sharpening service for optimal economy

Conclusion: The Final Cut

After countless projects and thousands of cuts with Hercules blades, I’ve come to a clear conclusion: they represent one of the best values in today’s tool market. While they may not dethrone the absolute premium brands for the most demanding applications, they deliver professional-grade results at prices that respect your budget.

What I appreciate most is the honest positioning of these products – they don’t claim to be the ultimate blades money can buy, but rather excellent tools at fair prices that will serve both professionals and serious DIYers with distinction.

If you’re looking to upgrade from entry-level blades without breaking the bank, or if you’re a professional seeking to optimize your consumables budget without sacrificing quality, Hercules saw blades offer the performance-to-price ratio that makes the most sense for the vast majority of cutting tasks.

Whether you’re building heirloom furniture or framing a house, these blades deserve a place in your tool arsenal. My workshop now contains more Hercules blades than any other brand – perhaps the most sincere endorsement I can offer as someone who demands quality results from every tool I use.